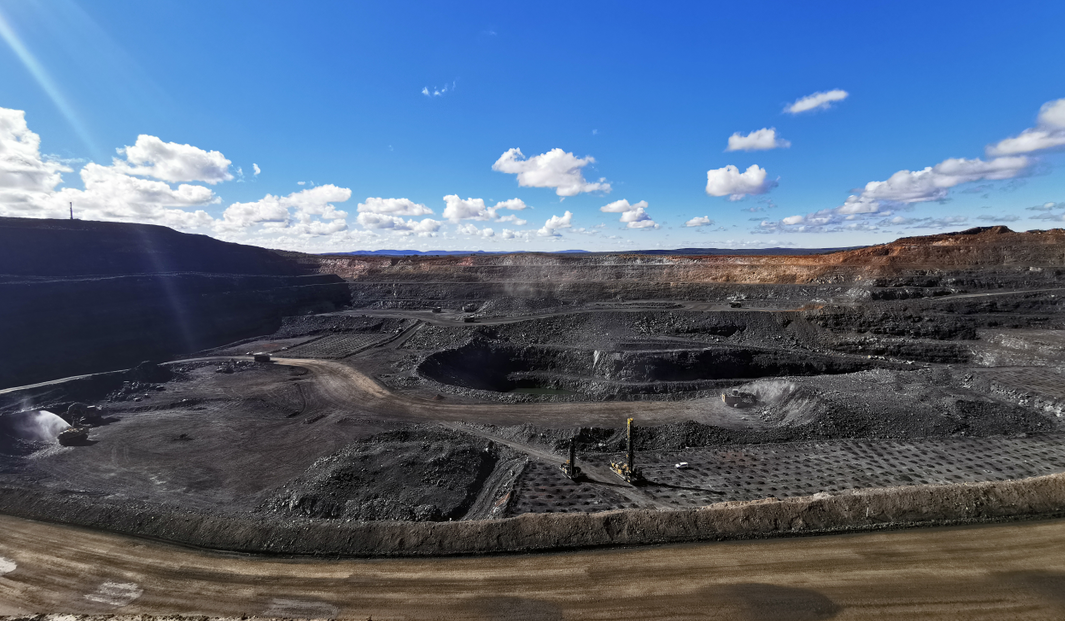

Chifukwa cha migodi yambiri ya zitsulo zachitsulo m'dziko langa, chuma chake chochepa chikuchepa kwambiri. Chifukwa chake, zofunikira pazida zopangira mchere zikuchulukirachulukira, makamaka kugwiritsa ntchito mozama kwa michira kumakhudzana mwachindunji ndi kulimbikira kwa chuma cha dziko langa. Funso ndi momwe angagwiritsire ntchito ndondomeko zosungira mphamvu, kuchepetsa kugwiritsidwa ntchito, ndi kuchepetsa utsi zomwe boma likufuna, kusunga kugwiritsidwa ntchito kwa nthawi yaitali kwa chuma, ndi kukulitsa mtengo wazinthu zakhala nkhani yofunika kwambiri yomwe ikuyang'anizana ndi migodi.

Pakadali pano, bwalo la ndege lomwe limagwiritsidwa ntchito pakulekanitsa maginito azitsulo zachitsulo m'dziko langa ndi pafupifupi 1600Gs, ndipo ndizovuta kupezanso maginito ofooka a maginito. Pachifukwa ichi, pakufunika kofunika kupanga zida zopezera phindu zomwe zili ndi mphamvu zapamwamba komanso zokhoza kuchepetsa zitsulo zachitsulo kuti zipititse patsogolo kugwiritsidwa ntchito kwa mchere m'dziko langa.

Shandong Huate Magnetoelectric Technology Co., Ltd. wadzipereka ku kafukufuku wa magnetite maginito kupatukana tailings kuchira zida kuyambira 2005. Pakali pano, ambiri ferrites amapangidwa monga maginito tailings kuchira makina, ndipo mndandanda atatu apangidwa. Zogulitsa zomwe zili ndi mafotokozedwe angapo zakhala zida zazikulu zowongolera ma tailings. Pofuna kuonjezeranso chitsulo chobwezeretsanso zida zobwezeretsanso tailings, pambuyo pofufuza mozama, kuwonetsa ndikuyesa kusanthula, kugwiritsa ntchito zida za neodymium iron boron maginito komanso njira yotsitsa m'malo omwe si maginito kwathandiziranso kuwongolera kwachitsulo. , ndipo kutsitsa ndikosavuta, komwe kumatha kukwaniritsa zofunikira zogwiritsira ntchito.

Kapangidwe ndi mfundo yogwirira ntchito yapakati pamunda mphamvu ya semi-magnetic yodzitsitsira makina otsitsira

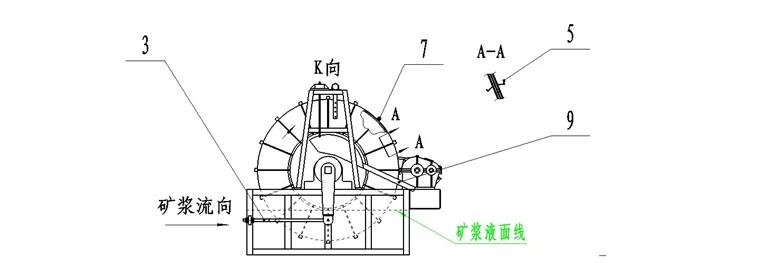

Makina apakati amphamvu a semi-magnetic tailing tail recovery machine amagwiritsa ntchito neodymium iron boron ngati maginito. Malo olekanitsa ali ndi maginito apakati komanso malo ofooka a maginito. Mitengo ya maginito imapanga maginito a semi-circular ring magnetic system. Chophimba chozungulira chimaperekedwa kunja kwa maginito. , Maginito amakhazikika, mbali ina ya chipolopolo imamizidwa mu zamkati, ndipo maginito particles mu zamkati amatengedwa mosalekeza ndi njira yozungulira mosalekeza. Tinthu tating'onoting'ono ta maginito timapitiriza kugwedezeka pamodzi ndi kuzungulira kwa casing, kotero kuti zinthu zopanda maginito zomwe zili mu maginito zimatsukidwa mosalekeza. Mbali yakumanja ya semi-annular magnetic system ilibe maginito. Pamene zipangizo za maginito zimalowa m'dera lopanda maginito, pansi pa madzi osamba ndi mphamvu yokoka ya zinthuzo, Tulutsani zinthuzo mu thanki yowonongeka.

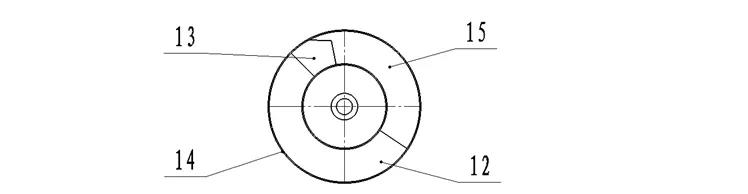

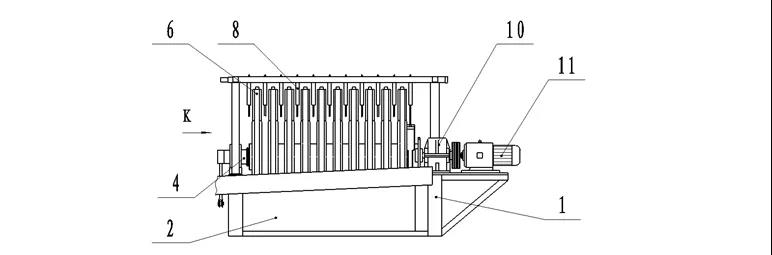

The mid-field mphamvu theka-magnetic self-unloading tailings recovery machine ndi chimbale-mtundu ophatikizana dongosolo, ndipo chiwerengero cha maginito zimbale akhoza kutsimikiziridwa malinga ndi zofunika za processing mphamvu. Mapangidwe ake akuwonetsedwa mu Chithunzi 1, 2, ndi 3. 1- chimango; 2 - thanki yamadzi; 3- disk kusintha makina; 4 - tsinde lapakati; 5 - deflector; 6-kusonkhanitsa thireyi; 7 - kusokoneza chipika; 8 - chitoliro chowombera; 9 - kugwira chute; 10 -Kuchepetsa; 11-motor; 12-mphamvu maginito dera; 13-malo ofooka maginito; 14-fixed disk; 15-non-magnetic dera.

Chimangocho chimapangidwa ndi chitsulo chowotcherera ndipo chimagwiritsidwa ntchito makamaka kuthandizira shaft yapakati, kukhazikitsa njira yotumizira ndikuyika tanki ya slurry.

Magnetic disc ndi semi-magnetic kapangidwe, ndipo chotsekera chotolera chimbale chimayikidwa panja, mbale ya maginito yolumikizira imayikidwa pakati pa chitsulo chawiri-wosanjikiza maginito, ndipo m'munsi mwa disc yotolerayo imamizidwa mu thanki ya slurry 2.

Magnetic disc amaperekedwa ndi maginito apakati, malo ofooka a maginito ndi malo osakhala ndi maginito, ndipo amakhazikika pakatikati pa axis.

Malekezero awiri a poto yosonkhanitsa amaperekedwa ndi mbale zambiri zowongolera zomwe zimagawidwa mu mawonekedwe a ray, ndipo zopingasa zogawanika mofanana zimaperekedwa pamphepete mwakunja.

Pakali pano, ma concentrators ena m'dziko langa amagwiritsa ntchito makina opangira ma sing'anga-munda-mphamvu disk tailings, koma chifukwa cha kuchepa kwa desliming zotsatira, maginito amayamwa pamene maginito amalowa m'dera lopanda maginito kuchokera kumtunda wa magnetic field, ndipo disk ndi scraper kuvala mwamsanga. , Kutengera zoletsa zina zomwe zikugwiritsidwa ntchito.

Poganizira zomwe zili pamwambapa, kampani yathu imatengera diski yapakati-mphamvu semi-annular disk yokhala ndi neodymium-iron-boron yotsekedwa mokwanira kuti ikhazikike pakatikati pa axis, ndipo axis yapakati imakhazikika popanda kuzungulira. Chiwaya chosonkhanitsira chozungulira, m'munsi mwa poto yosonkhanitsa imamizidwa mu slurry flow through kuti mutenge maginito. Galimoto ndi chochepetsera zimagwiritsidwa ntchito poyendetsa thireyi yosonkhanitsira kuti izungulira, ndipo maginito adsorbed amadutsa pakati pa maginito ndi mphamvu yofooka ya maginito, ndiyeno imatuluka ikafika kumalo osakhala ndi maginito, omwe amathetsa mavuto omwe ali pamwambawa.

Chiwaya chakuthupi chimakonzedwa pakati pa chiwaya chilichonse chotolera, ndipo maginito a poto amatsukidwa ndikutuluka m'mphepete mwa chute.

Njira yopatsirana imapangidwa ndi makina osinthira pafupipafupi, chochepetsera, cholumikizira, cholumikizira cholumikizira, ndi zina. Zigawo zomwe tazitchula pamwambapa zimayikidwa pakatikati pa shaft ndi chimango kuti zizindikire kusinthasintha kosalekeza kwa tray yosonkhanitsira.

Kabati yowongolera imakhala ndi ma inverters, zosinthira zowongolera ndi zida zina kuti ziwongolere kuthamanga kwa maginito disc nthawi iliyonse.

Maginito okhazikika m'dera la maginito amapangidwa ndi chidutswa chimodzi kapena zidutswa zingapo mumayendedwe a makulidwe, ndipo ukonde wokhazikika wa disc umayikidwa pakati. Maginito amatenga ma seti angapo a maginito ma pole awiri okhala ndi ma polarities osiyana kuti asamalidwe mosinthana. Pakusinthasintha kosalekeza kwa poto yosonkhanitsa, zida za maginito zimagwa nthawi zonse mu poto yosonkhanitsira komanso m'madzi kutsuka ndi matope, kotero kuti zida za maginito zomwe zapezedwa zimaphatikizidwa ndi michira wamba. Poyerekeza ndi makina obwezeretsanso, chiyero ndi chapamwamba ndipo zotsatira zobwezeretsanso ndizabwinoko.

Malo ofooka a maginito amaikidwa pakati pa maginito ndi malo omwe si maginito mu disk. Pamene maginito amalowa m'madera omwe si a maginito, chifukwa cha kufooka kwa magnetic field transition zone ndi mayamwidwe a malo ofooka a maginito amachepa pang'onopang'ono, kusuntha kwa msana kwa maginito kumachepetsedwa kwambiri. Kudodometsa kokhazikika pa thireyi yazinthu kumalepheretsanso kuyenda kumbuyo kwa zida za maginito ndi kutayikira kwa zinthu, ndipo zimatha kupangitsa kuti maginito asunthike pang'onopang'ono. Chifukwa cha mphamvu yokoka ndi madzi otsuka, kutsitsa mwachangu kumachitika.

Sireyi yosonkhanitsira ndi yopanda kanthu komanso yosindikizidwa bwino, ndipo pamwamba pa zinthu zopangira maginito amapangidwa ndi zinthu zopanda maginito. Pa thireyi yotolera, mbale yolondolerayo ili ndi nthiti kunja, yomwe imapendekera pamtunda wina ndi kumapeto kwa tray yotolera. Cholinga chachikulu ndikuletsa maginito. Kubwerera kumbuyo kwa zipangizo ndi kutayikira kwa zipangizo. Pofuna kuchepetsa kuyika kwa ore slurry, kuchuluka kwa zotchingira zoyambitsa matope zimakonzedwa mozungulira poto yosonkhanitsa, ndipo panthawi imodzimodziyo, kuyabwa kwa mbale yosonkhanitsira kumachepetsanso. .

Ntchito yopanga mafakitale

Kuwunika kwa kuchira kwa makina a midfield mphamvu ya semi-magnetic self-unloading tailings recovery

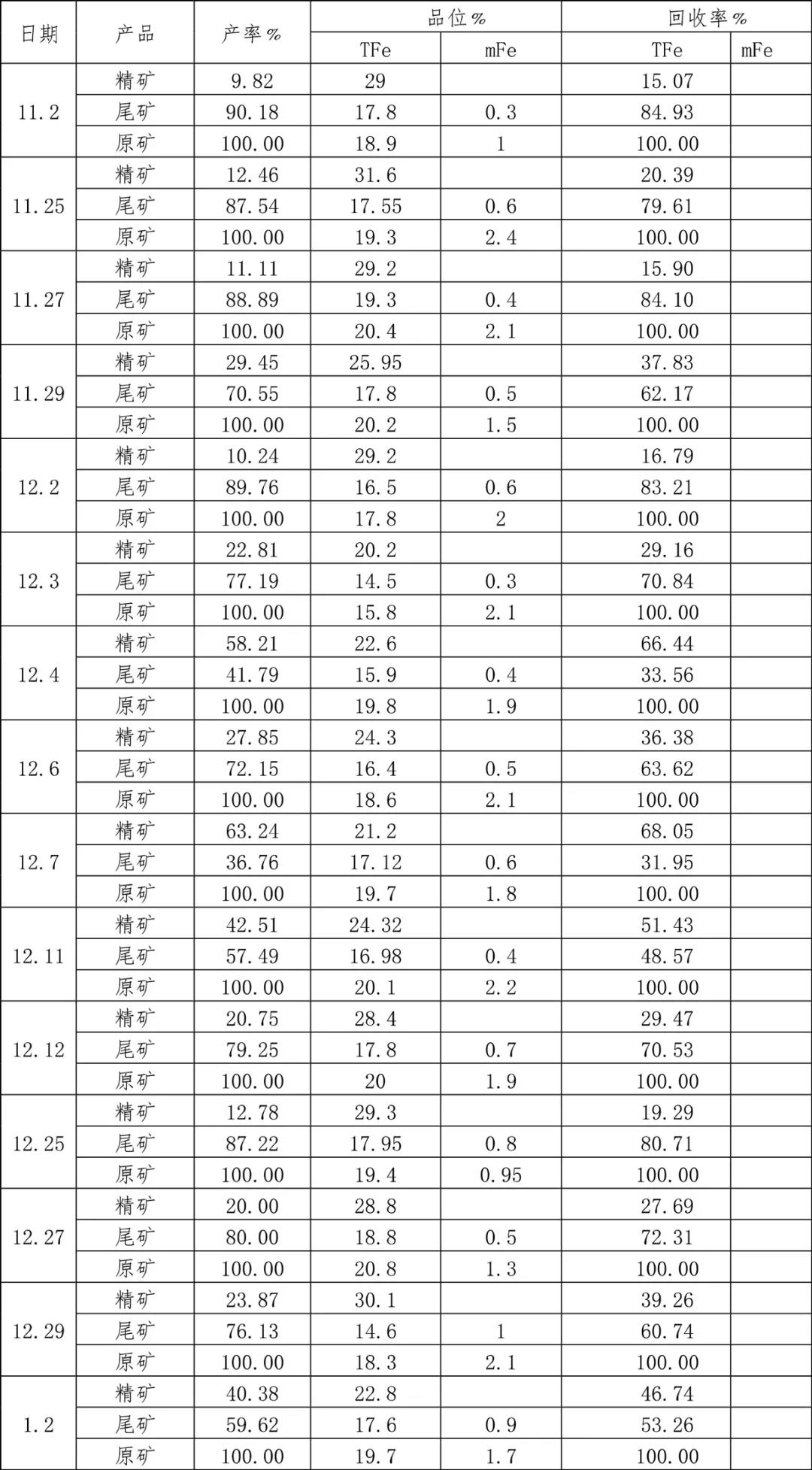

A sing'anga-munda mphamvu theka-maginito kudziletsa kutsitsa michira kuchira makina chitsanzo cha YCBW-15-8 kugwiritsiridwa ntchito ndi kampani migodi anaika kuseri kwa tailings kuchira makina wapangidwa ferrite mu dongosolo maginito. Pambuyo pa theka la chaka chogwira ntchito, Zidazi zikugwira ntchito bwino ndipo zotsatira zake zimakhala zabwino. Pambuyo poyesa zitsanzo zambiri, zotsatira zake zimakhala zokhutiritsa. Zotsatira za mayeso angapo a sampuli ndi izi:

Kupyolera muzomwe zili pamwambazi:

Kubwezeretsa kwa zida izi: kalasi ya michira imachepetsedwa ndi 2.16% mutatha kusanja, maginito achitsulo amachepetsedwa ndi 1.27% mutatha kusanja, ndipo kalasi yapakati ya ore ndi 26.53%. Kubwezeretsa zotsatira n'zoonekeratu.

Chiyembekezo cha msika ndi phindu lachuma

Pakalipano, pali mabizinesi ambiri olekanitsa maginito ku China, ndipo owerengeka okha ndi omwe amagwiritsa ntchito makina ochira a ferrite, koma osagwiritsa ntchito makina apakati pamunda mphamvu yamaginito odzitsitsa okha. Choncho, chiyembekezo cha msika ndi chachikulu. Ngati 20% ya maginito The processing zomera invests mu zipangizo, masamu potengera mayunitsi 300 pachaka ndi chitsanzo YCBW-15-8. Chigawo chilichonse chikhoza kuchira 7t/h ya ore youma pa ola, 168t/h ya ore youma patsiku, ndi masiku 330 ogwira ntchito pachaka, kuchira kwathunthu matani 55.44 miliyoni, ndipo matani okwana 16.632 miliyoni adasinthidwanso ndi mayunitsi 300. Phindu lazachuma ndi lalikulu, ndipo kugwiritsa ntchito zidazi kungachepetse kuwonongeka kwa mchere wambiri wa dziko chaka chilichonse.

Pakali pano, kalasi ya tailings achitsulo zitsulo m'dziko langa zambiri mkulu pambuyo kusanja, kuchititsa zambiri kuwononga chuma. Zida zamchere ndizo maziko a moyo ndi chitukuko cha anthu. Zoposa 95% ya mphamvu ndi 80% ya zopangira mafakitale m'dziko langa zimachokera ku migodi. Ndi chitukuko chofulumira cha chuma cha dziko langa, kufunikira kwa mineral resources kukukulirakulira. Kumbali ina, chuma cha dziko langa chikuyang'anizana ndi chitsenderezo chokulirapo chifukwa chosowa. Ma minerals apamwamba, osavuta kuwasankha akuchepa, ndipo zotsika mtengo, zovuta kuziyika zikuchulukirachulukira. Kupanga ndi kafukufuku wamakina obwezeretsa michira pamwamba pa 300mT kuli ndi zotsatira zabwino pakuchepetsa zinyalala zadziko ndikuwonjezera kuchuluka kwa kagwiritsidwe ntchito ka migodi. Kuchokera pamalingaliro a chitukuko ndi zotsatira zogwiritsira ntchito, zathandizira bwino kuchira kwa maginito ore. Imakwaniritsa zofunikira zamapangidwe ndipo ndi chinthu choyenera kukwezedwa ndikugwiritsa ntchito.

Nthawi yotumiza: May-12-2021